نمایش نتیجه 1 تا 10 از 11 نتیجه یافت شده برای BOP stack:

n: A large BOP (q.v.) valve that forms a seal in the annular space between the wellbore and the drill pipe. It is usually installed above the ram type preventers in the BOP stack.

a elastomer bag or donut type seal, pushed into contact with the pipe or tools in the blow out preventer (BOP). It is designed to seal around pipe or any other irregular surface tool (packers, guns, pumps, etc.) that may be in the BOP. May also be called

مجموع شیر فوران گیر

abbr: blowout preventer equipment. BOP stack n: the assembly of blowout preventers installed on a well.

n: a pipe attached to the blowout preventer stack out of which kick fluids and mud can be pumped to the choke manifold when a blowout preventer is closed in on a kick.

n: A high-pressure pipe leading from an outlet on the BOP stack to the backpressure choke and associated manifold. During well-control operations, the fluid under pressure in the wellbore flows out of the well through the choke line to the choke, reducing th

a drilling and workover pressure control device. A line that attached to the BOP stack and through which kick fluids can be circulated when the BOP is closed.

n: a device placed or hung in the casing below the blowout preventer stack to form a pressure-tight seal. Pressure is then applied to the blowout preventer stack to test it for leaks.

n: a kind of tool which is put or hung under the BOP stack unitization and used as wiper seal

a plug placed below the BOP prior to a pressure test.

n: on offshore floating rigs, a large spool, or reel, onto which the hose bundle is wrapped. The hose bundle consists of several control lines, some electrical and some hydraulic, that run to the control pods on the subsea blowout preventer. When the driller or other person actuates a BOP control on the rig at the surface, the control signal goes through the hose bundle to the control pod on the BOP stack.

a manufacturer of BOP and other well equipment. Also a common term for a section of the BOP stack that utilizes a large rubber “donut” that can seal on irregular surfaces or even on itself.

flow lines to the BOP stack, entering below the pipe rams, through which kill weight fluids can be pumped.

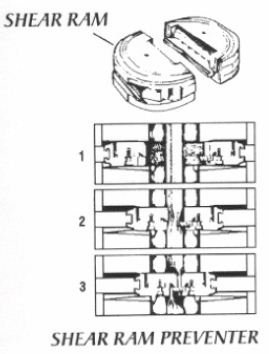

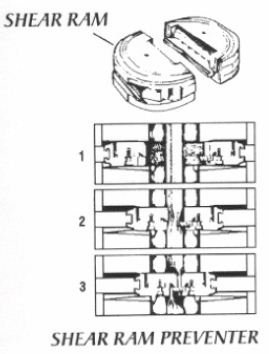

n: the component in a blowout preventer that cuts. or shears, through drill pipe and forms a seal against well pressure. Shear rams are used in floating offshore drilling operations to provide a quick method of moving the rig away from the hole when there is no time to trip the drill stern out of the hole.

n: the component of the BOP stack (q.v.) that cuts through the drill pipe and forms aseal across the wellbore. These are used on floaters when the rig must be moved off location in an emergency.

a ram in the BOP that shears off the pipe.

n: (SIP) the pressure when the well is completely shut in, as noted on a gauge installed on the surface control valves. When drilling is in progress, shut- in pressure should be zero, because the pressure exerted by the drilling fluid should be equal to or greater than the pressure exerted by the formations through which the wellbore passes. On a flowing, producing well, however, shut-in pressure should be above zero.

n: The surface force per unit area exerted at the top of a wellbore when it is closed at either the Christmas tree or the BOP stack. The pressure may be from the formation or an external and intentional source. The SIP may be zero, indicating that any open f

the pressure at a datum when the well is not flowing. The shut in pressure is usually either surface shut-in pressure or bottom hole shut-in pressure.

فشار چاه بسته