نمایش نتیجه 1 تا 10 از 55 نتیجه یافت شده برای perforate:

n: a device that secures, or fastens, equipment. In producing wells with sucker rod pumps, a gas anchor is a special section of perforated pipe installed below the pump. It provides a space for gas to break out of the oil. In offshore drilling, floating drilling vessels are often secured over drill sites by large anchors like those used on ships. For pipelines, a device that secures pipe in a ditch.

n: Means of holding the deadline to the derrick or substructure. Usually this is the primary element of the weight indicator

a device with slips that holds equipment in the wellbore.

لنگر- مهاربستن

دیواره ی مشبک ضد سایش

an unperforated piece of casing or tubing in an otherwise perforated section. Used for isolation.

n: a technique in squeeze cementing in which (1) the zone below the producing interval is perforated and a high pressure squeeze carried out;(2) the zone the producing interval is perforated and squeezed off in a similar manner;(3) the hole is drilled out;and (4) the producing interval is perforated. The purpose of block squeezing is to isolate the producing interval and prevent communication with the sand immediately above and below the producing interval.

a cement squeeze into a area of perforations. Often done initially over the frac pressure.

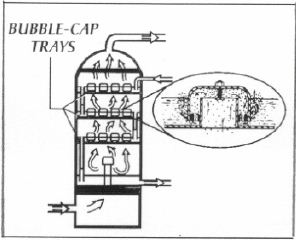

n: a perforated steel tray on which bubble caps are mounted. Bubble caps and trays are arranged in bubble towers, cylindrical vessels set vertically. See sieve tray. valve tray.

n pI: the devices loaded into perforating guns to penetrate casing and cement and for some distance into the formation when the guns are fired. See gunperforate.

cased and perforated.

a completion technique where casing is cemented in the drilled hole and perforations are placed at the most promising flow points based on log interpretations.

cased, cemented and perforated.

n: a variation of squeeze cementing for wells with two producing zones in which (1) the upper fluid sand is perforated;(2) tubing is run with a packer, and the packer is set between the two perforated intervals;(3) water is circulated between the two zones to remove as much mud as possible from the channel;(4) cement is pumped through the channel and circulated;(5) the packer is released and picked up above the upper perforation, a low squeeze pressure is applied, and the excess cement is circulated out. The process is applicable where there is communication behind the pipe between the two producing zones because of channelling of the primary cement or where there is essentially no cement in the annulus.

a secondary or repair cement method using upper and lower perforations and a packer set between. Circulation is established with water and mud remover chemicals to clean the channel. Cement is circulated with a set volume pumped, then the packer is releas

© ۱۳۹۲-۱۳۹۷ این اثر شامل قانون حمایت از مولفین بوده و هرگونه کپی برداری از آن ممنوع است.